Reinforced Polyethylene Liner

Minimal Downtime.

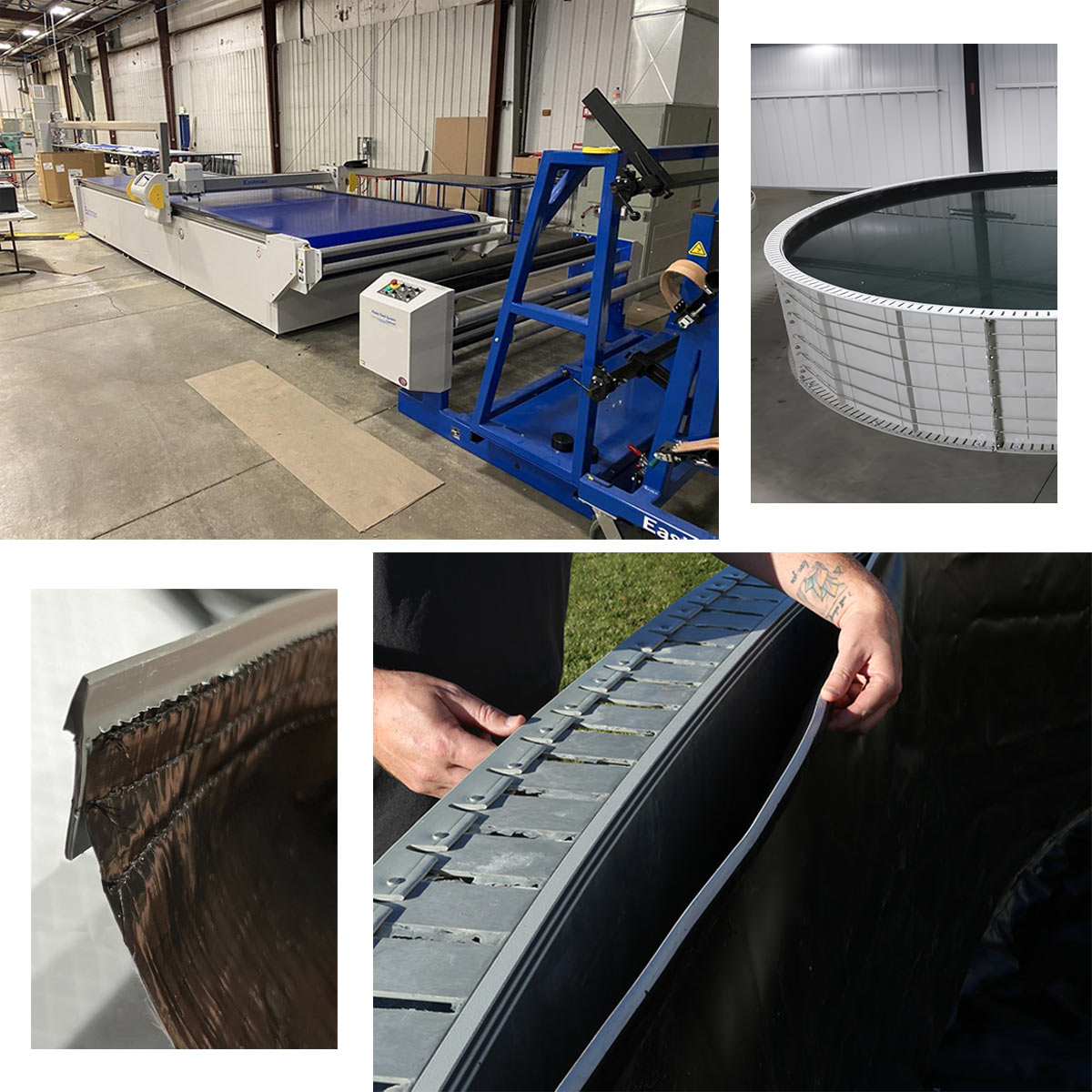

Part of what makes our tanks modular is the industry exclusive drop-in membrane liner. This liner is installed as part of a complete PATENT PENDING system that includes our dual bead track, membrane liner, and containment net. Custom-engineered, the liner is made of a string reinforced, polyethylene material. The material is Custom-Fit in OUR FACTORY for each tank which means there are no folds to trap waste or create excess wear. It is attached to the tank by being securely fitted into a Bead Track which is mounted at the top edge of the tank wall. Complete water retention without hassle.

Easily Serviceable.

Our liners were designed specifically with aquaculture and aquaponics industries in mind. While our tank liners can be cleaned after each growth cycle if desired, extending their life, our tank and liner modular system is engineered to reduce the traditional downtimes associated with tank cleaning and refinishing. Instead of lengthy, labor and chemical intensive cleaning, our quick-change liner system allows the used membrane to be quickly removed and a new form-fitted liner to be installed in its’ place, then filled with water. Your tank system can be back in service in no time!

INSTALLATION PROCESS.

Our tank liners make first-time installation or replacements EASY.

- Liner is laid out in the tank and bead is pulled up to the top edge of the tank.

- Liner bead is securely fitted into the bead track

- Fill with water

- Ready for another cycle!

1.

2.

3.

4.

USE OUR LINER SYSTEM WITH ANY TANK.

Renovate your existing tank.

The beauty of our modular liner and bead track system is that it can be applied to existing tanks as well. We refer to this application as our Tank Reconditiong System.

Simply install the bead track at the top of your existing wall, we will custom-manufacture a liner to the dimensions of your tank, and with that form-fit liner installed, your tank is now using our MODULAR liner system.